Precision-Cooled

Performance Block

Precision-Cooled. Performance-Driven

Aegis delivers the industry’s first full-stack, two-phase flow boiling, liquid cooling system, engineered for today’s most demanding compute environments.

This closed-loop, modular solution provides unmatched cooling density, real-time responsiveness, and rapid scalability — from edge to hyperscale.

Built to scale. Built for AI.

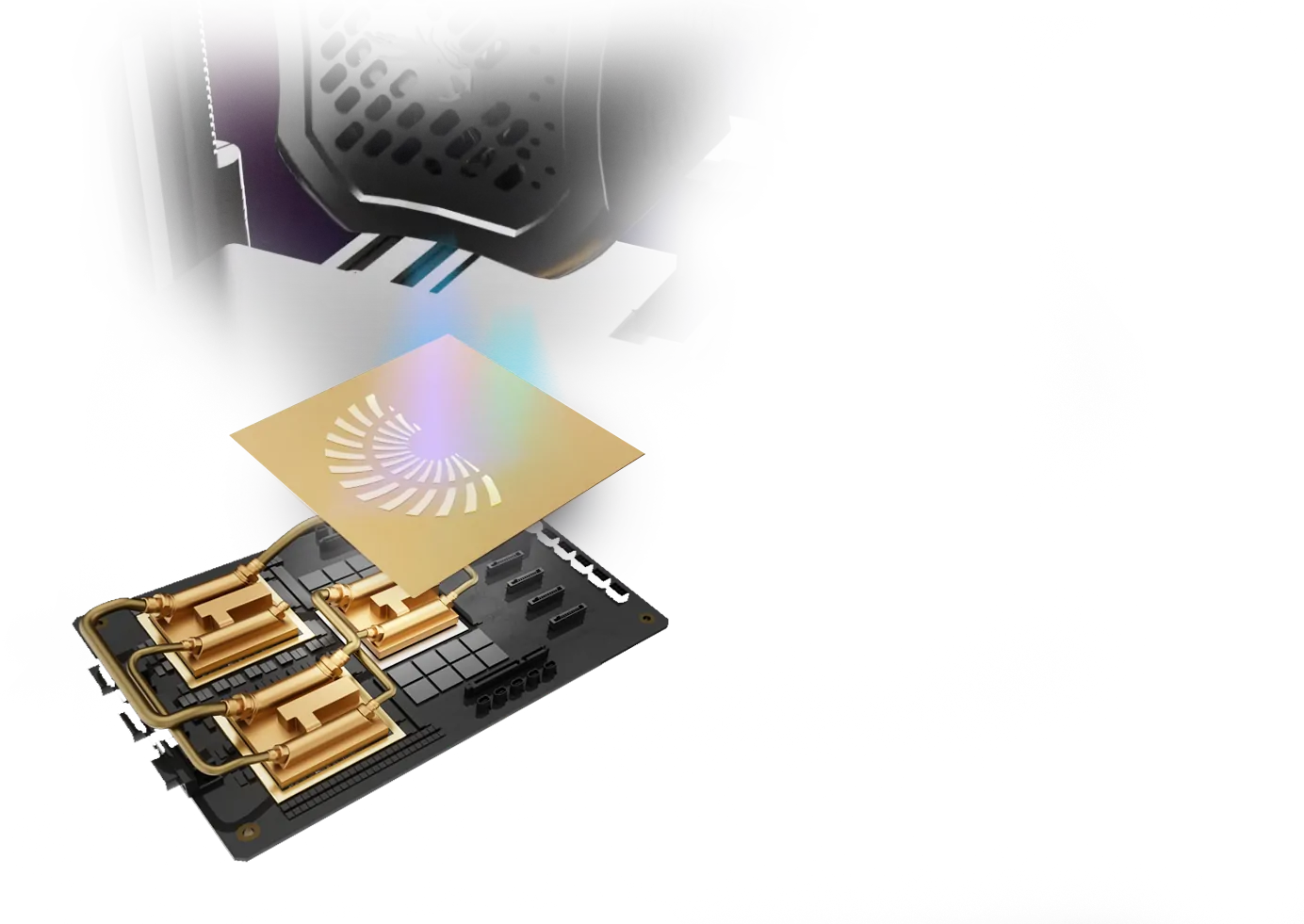

3D-Printed Microchannel Plate

One Print. No Compromise

Aegis cold plates are fully 3D-printed in a single pass — no welding, no assembly, and no thermal tradeoffs.

Our thin-wall, microchannel design delivers ultra-compact, high-efficiency heat transfer with:

- 50% lower thermal resistance than machined plates

- Up to 80% material savings and significantly reduced weight

- Custom geometries for emerging chip architectures

Additive by nature. Aggressive by performance.

Direct Vaporization at the Heat Source

Boil Where It Matters

Aegis uses two-phase flow boiling directly on-chip — combining the best of boiling and forced convection. By flow boiling, we could achieve:

- Instant thermal responsiveness

- Lower junction temps and tighter deltas

- Stable and Consistent flow inside the microchannel

It’s not immersion. It’s precision.

Development Speed & Lead Time

Thermal Design in Days. Not Months

From digital simulation to printed cold plate prototype, our thermal development cycle is measured in days, not quarters.

- Full DfAM (Design for Additive Manufacturing) flow

- 7-day concept-to-print turnaround

- U.S.-built systems delivered in 60 days

- No MOQs — scale up when you’re ready

Engineered for iteration. Built for acceleration.

Agile Manufacturing

Global Supply Chain? No Thanks

Aegis eliminates tooling delays and freight bottlenecks with localized, just-in-time production.

- Metal 3D printing replaces CNC queues

- Materials sourced from U.S. and EU

- 48-hour SLA on critical spares

- 60-day lead time from order to rack-ready system

From design to deployment — without crossing an ocean.

Sustainability

Zero Water. Near-Zero Waste

Aegis liquid cooling is as efficient for the planet as it is for your servers.

- Closed-loop dielectric means WUE = 0

- Additive manufacturing eliminates machining waste

- pPUE could be as low as 1.05

- No immersion oils, no drain tanks, no hazardous handling

- Reduced shipping and packaging footprint

High performance, low impact.

Performance Metrics (Stats)

Quantified. Verified. Delivered.

Aegis is built for measurable, repeatable, real-world results.

| Metric | Performance |

|---|---|

| Thermal Resistance | ↓50% vs CNC plates |

| Design-to-Print Time | 7 days |

| System Lead Time | 60 days |

| Water Usage | 0 L (WUE = 0) |

| pPUE | ≥ 1.05 |

| Material Efficiency | ↑80% (via 3D printing) |

This is what next-gen cooling looks like in numbers.

Technology + Awards Overview

Built to Win. Proven to Lead

Aegis technology is trusted by the world’s most demanding compute environments — and recognized globally for innovation.

Recent awards and industry validation:

- DCR Excellence Award 2025 – Data Centre Cooling Product of the Year

- Frost & Sullivan 2025 – North American Cooling Company of the Year

Backed by Airsys, built by the team delivering next-gen AI thermal infrastructure.

Recognized. Reliable. Ready to scale.

Ready to Print Your Thermal Future?

Engineer Your AI/HPC Thermal Strategy with Aegis