TurboPlate™

3D-Printed Heat Sinks Reborn

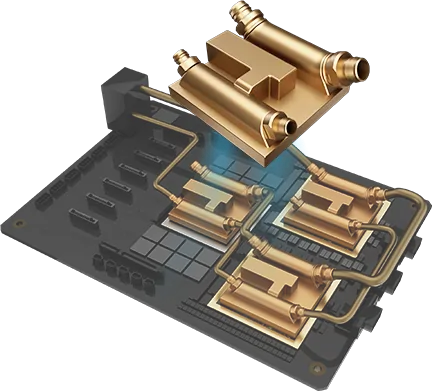

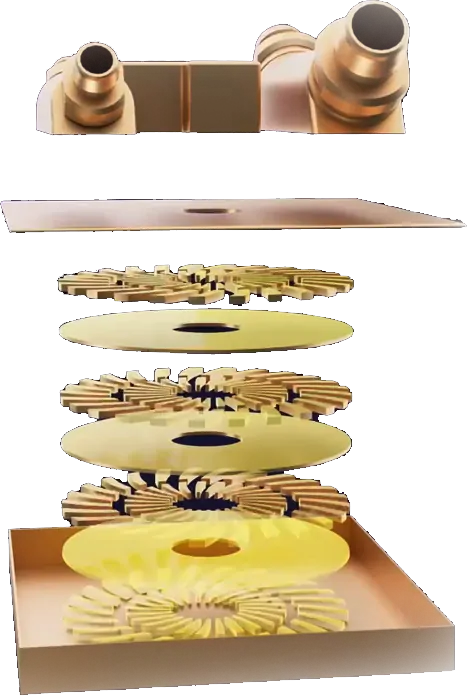

3D-Printed TurboPlates™

5000W AI Cooling Solved

Direct-to-Chip Two-Phase Cooling x 3D-Printed TurboPlate™

Manufactured in the USA, engineered for 5000W TDP era

Why Direct-To-Chip?

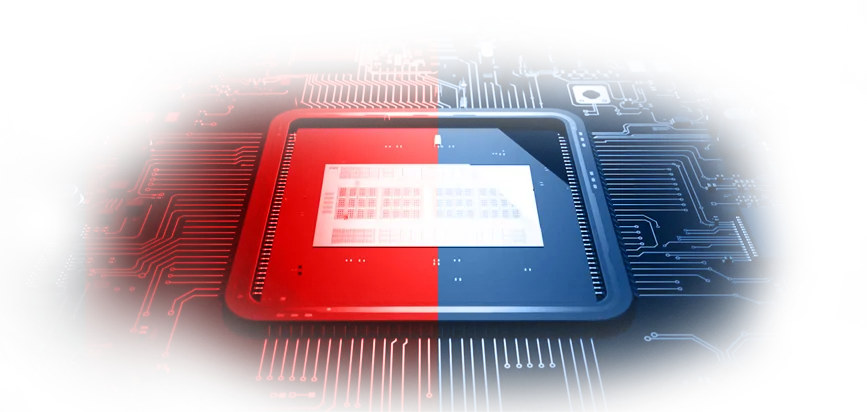

AI Heat Is Rising Beyond Limits

Heat density is now the biggest bottleneck in AI infrastructure. NVIDIA forecasts a 4x increase in heat output from 2025 to 2027 — doubling every 6 months. Traditional cooling just can’t keep up.

Aegis’ Solution

- Two-Phase Evaporation Direct CPU contact results in faster heat transfer

- 3D-Printed TurboPlate™ customisable solution with decentralised manufacturing

- VaporCool-X™ Leak-proof + dual-pump redundancy

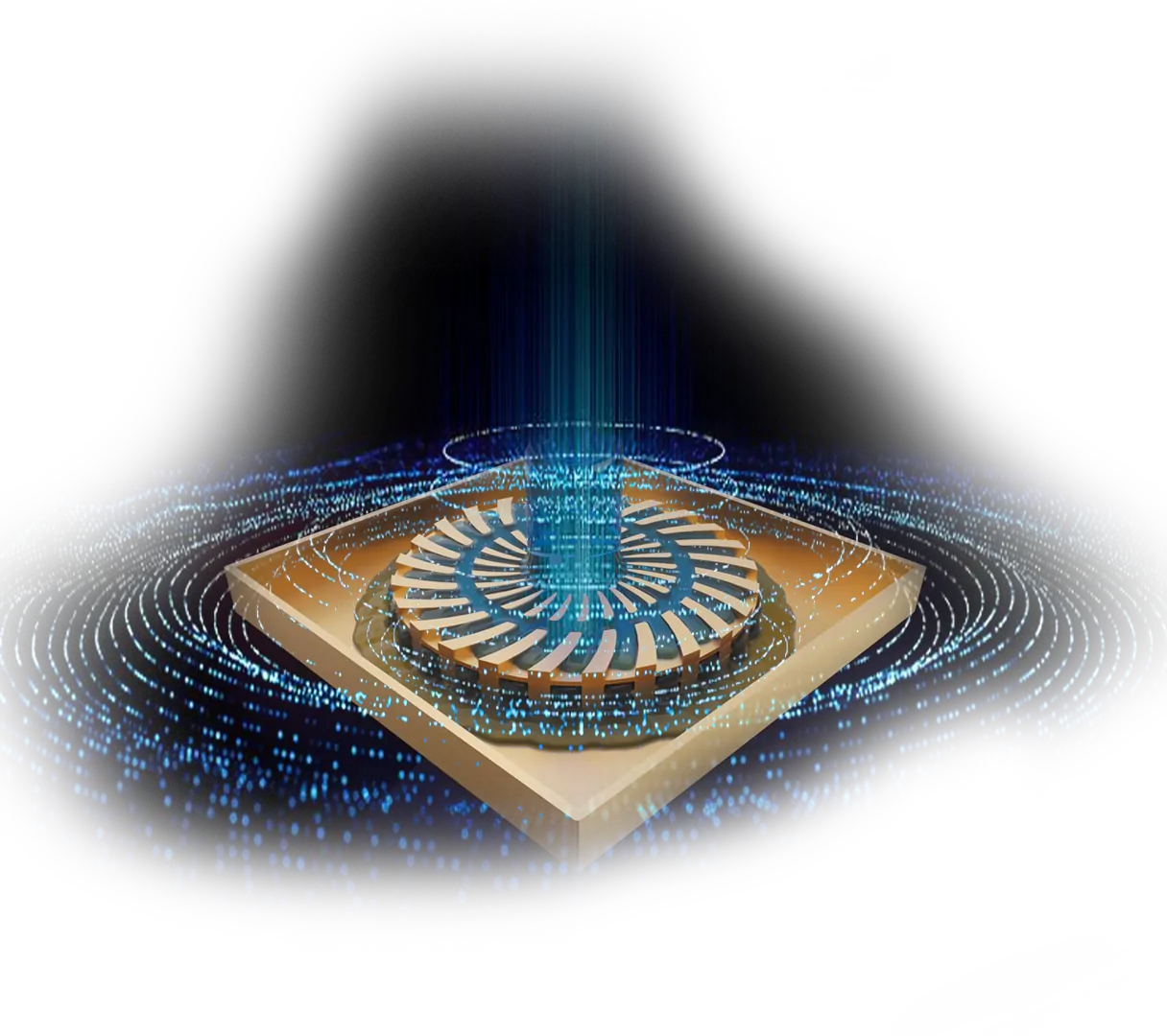

TurboPlate™ Chip-Level Engine

TurboPlate™ Core Advantages

- 3D-Printed Microchannels – 50% lower Rth vs CNC machining

- Two-Phase Supercooling – Designed to Handle Next-Generation AI Thermal Loads

- Rapid US Production – 80% Reduction in Design Validation Time,50% Shorter Supply Lead Time Over Legacy Cooling Approaches

TurboPlate™ Chip-Level Engine

Customer Outcomes

- Ultra-sustained chip performance upto 5000W TDP

- Faster thermal solution iteration

- More rack space/energy savings

- Zero logistics risk

This thermal breakthrough redefines AI cooling

“As next-generation GPUs push the boundaries of power and cooling, Airsys sets itself apart with its innovative 3D-printed, two-phase microchannel heat sinks, engineered to tackle these challenges. Specifically designed for high-density, high-power GPUs, this advanced solution optimizes heat rejection and reuse, ensuring superior thermal management and energy efficiency.”

— Frost & Sullivan, 2025

VaporCool-X™ Intelligent Vapor Control

VaporCool-X™: Rack-Smart Cooling Control

VaporCool-X™ is the first in the industry to adopt patented Vapor Quality.

Control technology. This innovation enables real-time regulation of vapor phase change, ensuring dynamic balance between fluctuating IT loads and pump speeds for optimized thermal performance.

Energy-Efficient Pumping

Variable-speed refrigerant pump reduces power consumption by up to 50%.

Improved PUE

Lower system power use leads to better overall energy efficiency.

Key Tech Features

- Dual-pump safety: 100% uptime with <1s leak shutdown

- “Click-to-cool” expansion for new AI servers

- 100% US-sourced critical components

Customer Outcomes

- Unlock 250kW/Rack Thermal Headroom – Redefine AI ROI Timelines

- CapEx Scales alongside Tensor Demands – Not Cooling Limits

VaporCool-X™ Safety & Scalability

- <1s Leak Lockdown – Auto-sensors trigger instant flow cutoff

- Zero Downtime – Dual pumps & power feeds switch seamlessly

- Hybrid Cooling – Air-liquid synergy for non-chip components

- Rack-Ready – Slide-in modules, zero infrastructure changes

TurboPlate™ + VaporCool-X™ = Total Thermal Control

From CPU to data hall: 3D-printed microchannels extract heat at the source, smart VaporCool-X™ circulate and monitor coolant, and recovered heat is repurposed — enabling predictable thermals, accelerated deployments, and a reduced carbon footprint.

Sustainability Built on Data, Backed by Science

- Water-Free Operation (WUE = 0)

- 80% Material Efficiency with Additive Manufacturing

- Battle-Tested in: MRI Systems | Semiconductor Lithography | Hyperscale AI

- Onshore Production Secures Supply Chains

Cooling Redefined

Printed for Peak Performance